The oil and gas industry is an important part of the global energy supply, but it is also one of the industries with the greatest impact on the environment. In order to reduce the impact on the environment and ensure the sustainable use of resources, the industry has taken a variety of measures, one of which is the application of cathodic protection technology. Cathodic protection technology is widely used in oil and gas pipelines, storage tanks, offshore platforms and other facilities to extend their service life and reduce the risk of leakage caused by corrosion.

Cathodic protection (CP) is an electro-chemical protection technique used to prevent corrosion of metal structures in an electrolyte environment. This technology slows or stops the corrosion process in facilities by applying an electric current to metal surfaces. There are two main types of cathodic protection: sacrificial anode protection and impressed current cathodic protection

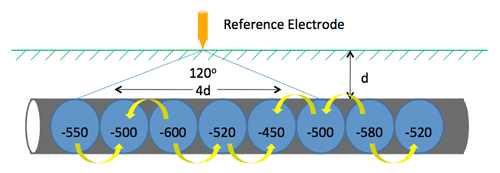

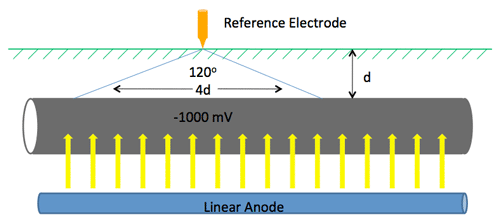

Cathodic protection of pipelines

Pipeline without CP applied

CP applied to pipeline

1. Sacrificial anode protection:

In this method, a metal that is more reactive than the metal being protected (such as magnesium, zinc or aluminum, etc.) is used as the anode. When the anode is connected to the metal being protected and exposed to an electrolyte (such as soil or water), the anode will corrode preferentially, thus protecting the primary metal structure.

Advantages:

● Relatively low initial investment and operating costs

● Spontaneous chemical reaction, reducing maintenance complexity and costs

● No harmful by-products, little impact on the environment

● Directly fixed on the protected metal, easy to install

Disadvantages:

● Requires regular inspection and replacement, increasing long-term maintenance costs

● May not fully cover large or complex structures

● Corrosion products may affect metal surface properties

● May not work well in high resistivity waters

2. Impressed current cathodic protection:

Impressed current cathodic protection is a commonly used technology to prevent metal corrosion, especially in the fields of marine engineering, petrochemicals, water treatment, etc. This method involves using an external power source to provide an electric current by connecting the metal structure to the negative pole of the power source, connecting an auxiliary anode to the positive pole, and the current flows from the anode to the protected structure.

Advantages:

● High adjustability, can adapt to different environments and materials

● Low maintenance cost and long service life

● Wide adaptability, suitable for a variety of water qualities and environments

● Remote monitoring, easy to manage and adjust

Disadvantages:

● Large initial investment, requiring professional equipment and technology

● May interfere with nearby metal structures

● Regular maintenance inspection is required

● Improper operation may cause impact on the environment

In the oil and gas industry, the design, installation and maintenance of cathodic protection systems are very important. Proper cathodic protection can significantly extend the service life of equipment, reduce maintenance costs, and ensure safety and environmental protection.

Date: 26 Jul 2024

中文

中文